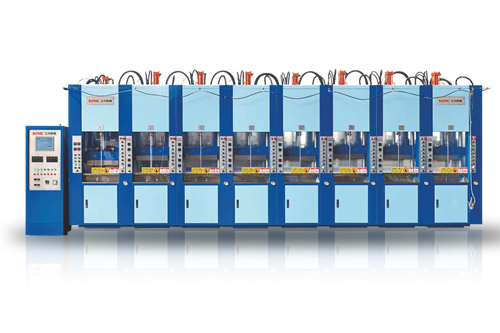

This EVA injection moulding machine is suitable for the production of single-colour foam products like rain boots, midsoles, slippers, sandals, yoga sticks and cushions. It can handle raw materials of EVA and rubber particles.

| Item | Unit | | |

| Raw materials | EVA, Rubber | ||

| Stations | 6 | 8 | |

| Screw diameter | mm | 60/65*2 | |

| Maximum injection volume | CC | 980/1150*2 | |

| Injection pressure | MPa | 120 | |

| Clamping force | Tons | 220 | |

| Yield | Pairs/hour | 180-250 | 200-300 |

| Mould space | mm | 290*550*2set | |

| Mould opening stroke | mm | 350 | |

| Mould thickness | mm | 100-330 | |

| Injection cylinder diameter/stroke | mm | ∅250*350 | |

| Screw power | kW | 14 | |

| Template heating power | kW | 12*6 | 12*8 |

| Servo motor power | kW | 52 | |

| Total power | kW | 138 | 162 |

| Dimensions | cm | 790×470×300 | 970×470×300 |

| Machine weight | Tons | 25.6 | 32.7 |

| Oil consumption | L | 1200 | |

- Large template design and superior clamping force;

- Shuttle table allows for smooth station switching;

- This linear EVA injection moulding machine has a constant temperature system and a powerful vacuum system;

- Screw rod is made through special techniques that ensure durable and effective performance;

- Safety measures involving different machine parts have been taken;

- Efficient feeding system is configured to save a lot of time;

-

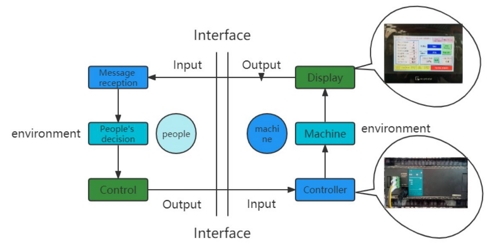

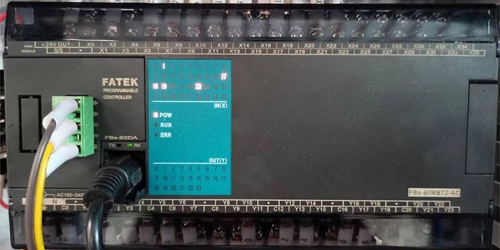

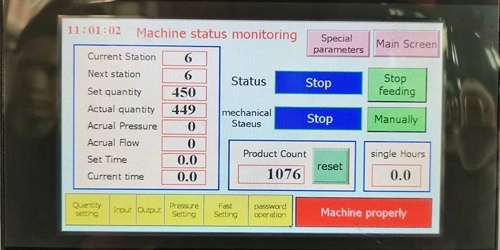

Standard industrial human-machine interface (HMI) and PLC control system are installed;

-

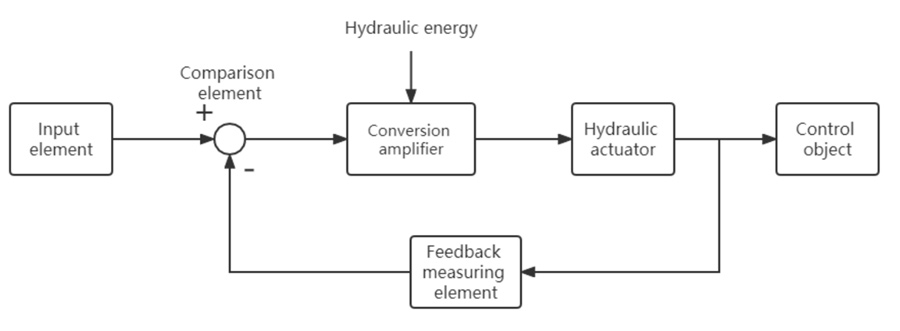

Servo system is installed to save energy and reduce costs;

-

Cooling tower cools down hydraulic oil and raw materials before they are fed into the injection moulding machine;

-

Air compressor is connected to the shoe injection moulding machine to ensure enough air supply;

-

Drying system is used to avoid bubbles in finished products and make better foam soles;

| Parts list | ||

| Toolbox | / | 1pc |

| Allen key | 1.5-10 | 9 sets |

| Allen key | 12 | 1pc |

| Allen key | 14 | 1pc |

| Allen key | 17 | 1pc |

| Open-end wrench | 8-32 | 6 sets |

| Open-end wrench | 41-46 | 1pc |

| Slotted Screwdriver | 6# | 1pc |

| Phillips screwdriver | 6# | 1pc |

| Adjustable wrench | 375-46 mm | 1pc |

| Vacuum pump oil | / | 1 liter |

| O-ring | 60*3.1 | 2pcs |

| O-ring | 95*3.1 | 1pc |

| O-ring | 120*3.53 | 1pc |

| O-ring | 140*3.1 | 1pc |

| O-ring | 200*5.7 | 1pc |

| O-ring | 195*3.1 | 4pcs |

| O-ring | 160(inner)*3.1 | 2pcs |

| O-ring | 40*2.65 | 2pcs |

| O-ring | 20*3.1 | 1pc |

| Pressure gauge | 400KG | 1pc |

| Vertical pressure gauge | 400KG | 1pc |

| Heating rod | Φ16*500 | 4pcs |

| Solid state relay | / | 5pcs |

| Proximity switch | Q18-05NK | 5pcs |

| Heating ring | φ118*50 | 1pc |

| Heating plate | 250*65 | 1pc |

| Thermal resistance | / | 5pcs |

| User manual | / | 1 |

| Ground anchor plate | CB001 | 40pcs |

| Pneumatic spray gun | / | 4pcs |

| Upper mould locking bolt | CB002 | 30pcs |

| Mould locking bolt gasket | CB003 | 30pcs |

| Lower mould locking bolt | M12X65 | 48pcs |

| Spray gun | / | 4pcs |

| Mould coupling | CB004 | 16pcs |

| Thermocouple | / | 4pcs |

| Gas pipe | φ8 | 30meters |

| Gas pipe fittings | φ8 Tee | 10pcs |

| Gas pipe fittings | φ8 Coupling | 10pcs |

| Gas pipe fittings | Z1/4-8 Coupling | 10pcs |

| Gas pipe fittings | Z1/4 Quick connect coupler | 10pcs |

| Wire rope | / | 8meters |

| Rope tensioner | / | 4pcs |

| Wire buckle | / | 4pcs |

| Pulley | / | 4pcs |

| Cable tie | 10*500 | 1pack |

| Cable tie | 5*250 | 1pack |

| Nut | M27 | 36pcs |

| Magnetic switch | 3pcs | |

| Temperature controller | H-D48 | 3pcs |

| Current meter | 85L17-300/5 | 1pc |

| Current meter | 85L17-1A | 1pc |

| Blower | 120*120-220V | 1pc |

| Double proportional valve amplifier board | / | 1pc |

| Drive board | 127 | 2pcs |

| Alarm lamp | 24V yellow | 1pc |

| Warning buzzer | / | 1pc |

| 5-way 2-position pneumatic valve | 24V | 2pcs |

| High temperature valve | 24V-3/8 | 2pcs |

| Sliding block | 35 | 1pc |

| Non-return valve | 55 | 1pc |

| Bushing | φ45*φ55 | 5pcs |

| Torpedo nozzle | / | 1pc |

| Check ring | / | 1pc |

| Transition ring | / | 1pc |

| Pneumatic combination unit | / | 1pc |

| Vacuum gauge | / | 2pcs |

SONC is a team of shoe machine experts with firm commitment to providing global footwear manufacturing plants with premium shoe manufacturing equipment. Our portfolio of footwear making machine mainly covers shoe sole making machines, sandal making machines, slipper making machines, flip flop strap making machines and rain boot making machines. Apart from our shoe machines, we also provide injection moulding machines for making other plastic or rubber products, such as mobile phone case making machine and rubber tyre making machine. As a specialist shoe injection moulding machine manufacturer, SONC can provide footwear machinery suitable for handling various materials including TPU, PVC, TPR, TR and EVA. Please get in touch with us if you are interested in our shoes machines or injection moulding equipment for other plastic and rubber products.